Menu

Behind the scenes look at how we make custom ear moulds and hearing aids.

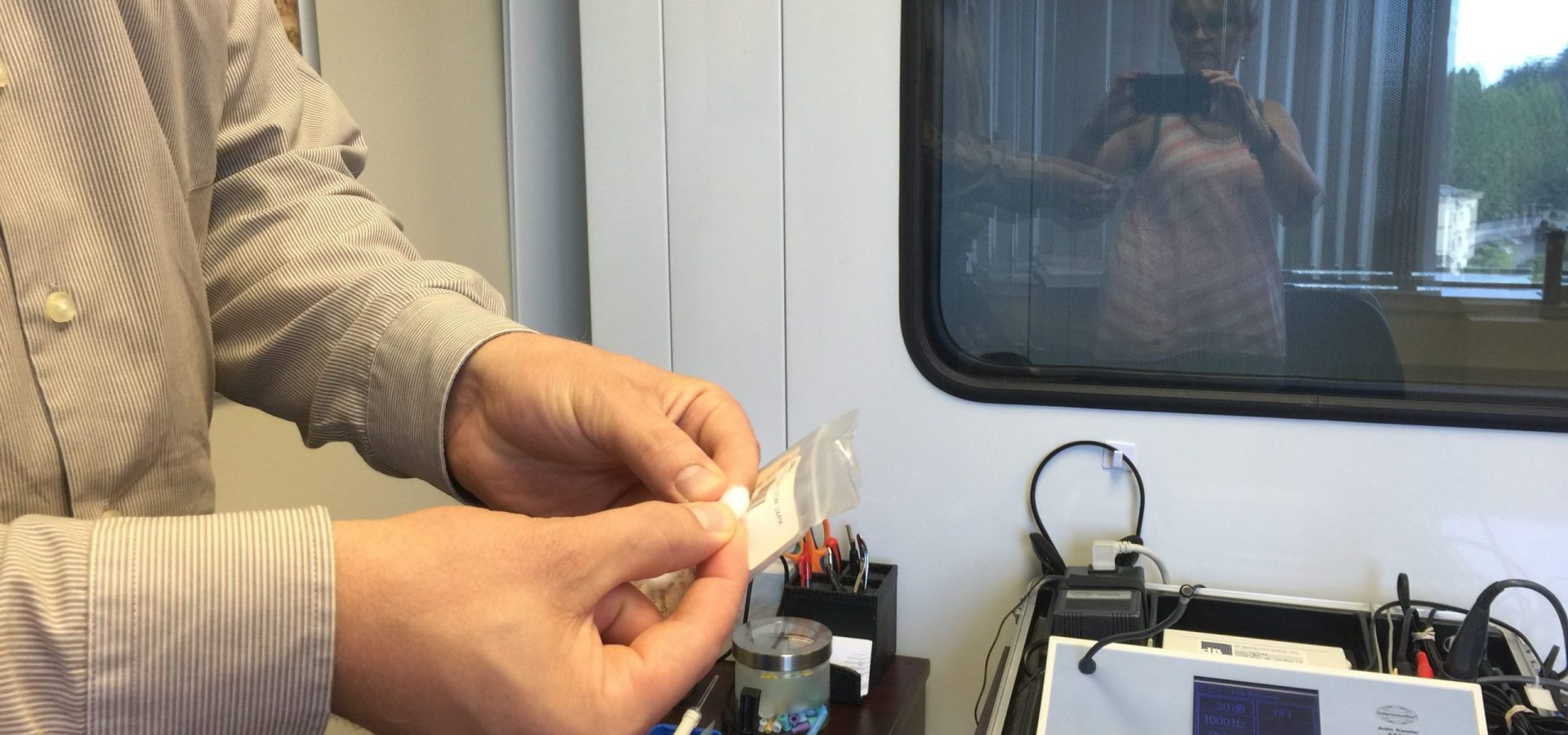

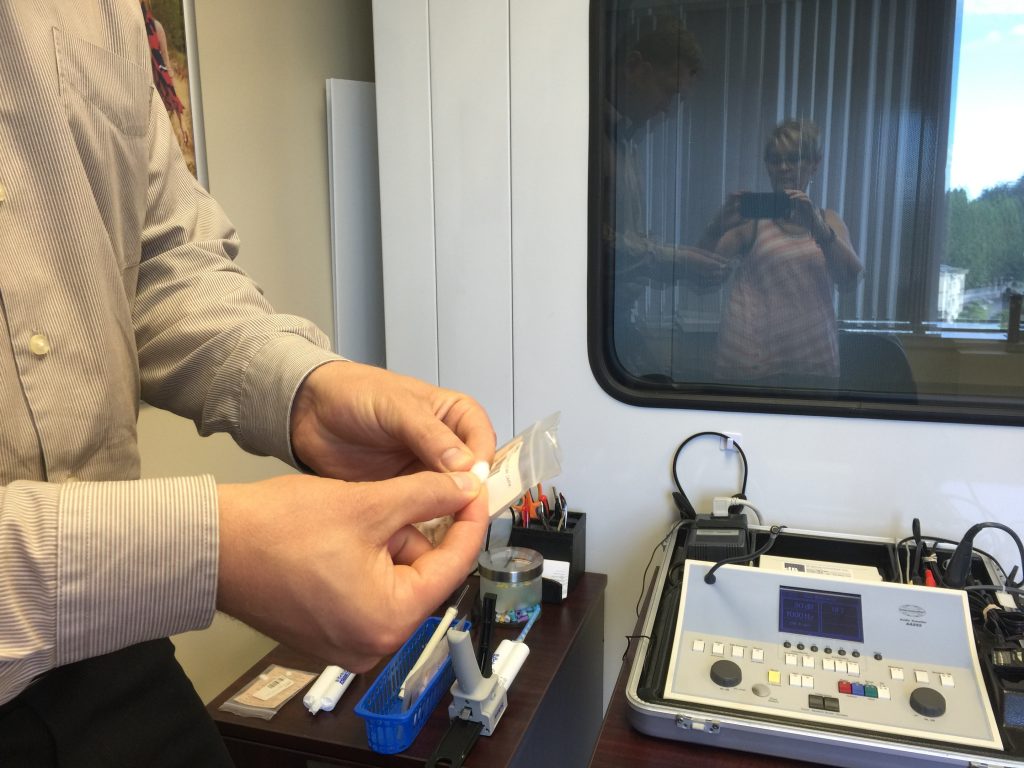

This is the dam we use to block the ear canal (called an oto block), preventing the impression material from going in too far.

First we need to perform an otoscopic examination to ensure there is no wax buildup or other obstacles as well as to get an idea of the size and shape of the ear canal.

Next we place the oto block in the canal and ensure it fully block the canal so none of the impression material gets past.

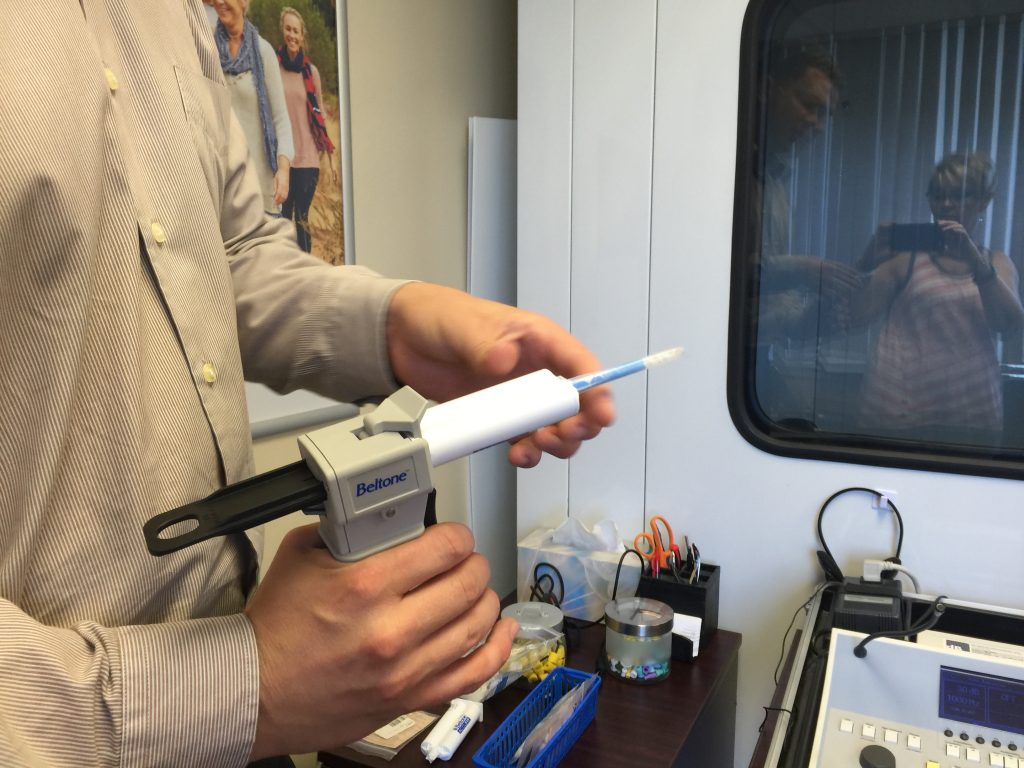

This is the impression material. It goes in in a liquid form and comes out in a solid form. It takes about five minutes to set.

We must ensure the material fills the ear to ensure an accurate fitting.

Don’t forget the other side!

After five minutes (ish) we have the mould of the ear to make the skookum custom hearing device for you!

Share Post

Facebook

Twitter

LinkedIn

Email

Reddit

Pinterest